CAM解決方案

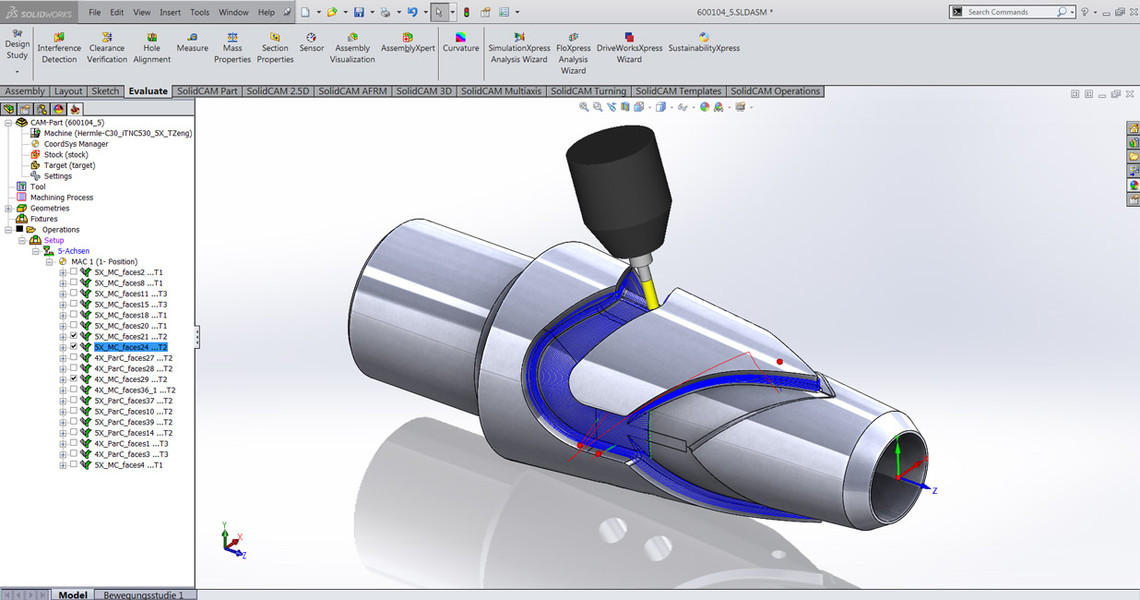

5軸同動加工

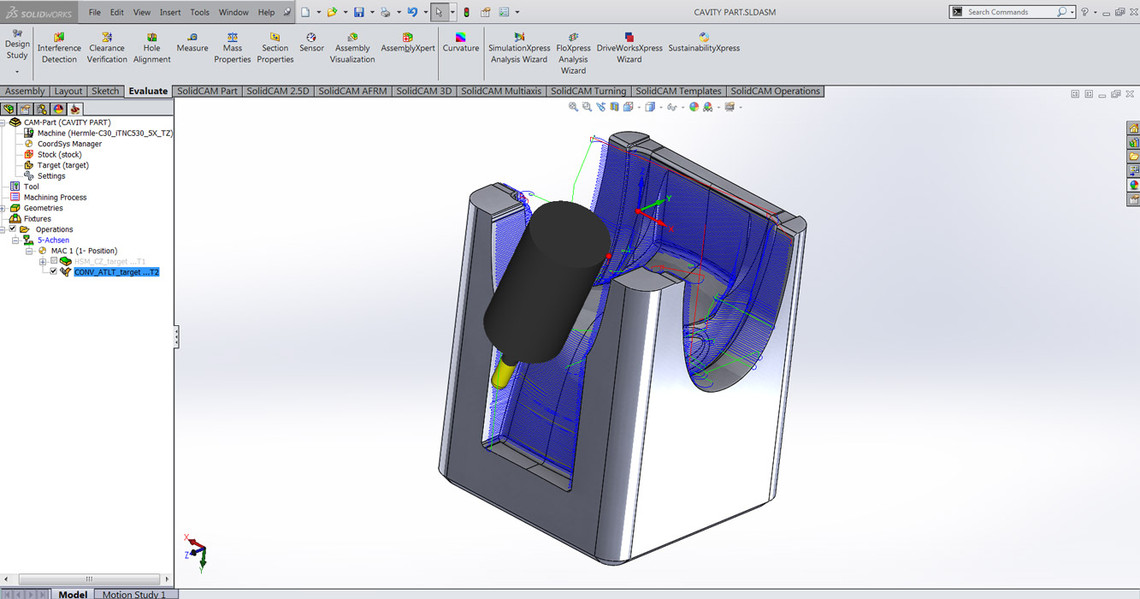

Benefit from the most tested and proven 5-axis CNC milling tool paths in the industry, with a very straight-forward user interface, and the mostadvanced control over all aspects of tool path and collision checking.

- Choose from the most complete library of Simultaneous 5-Axis cutting strategies that get you up and cutting instantly.

- Collision Avoidance protects both the tool and holder with a wide range of strategies, and machine simulation provides complete, graphical Cutter and Tool-holder gouge checking.

- Each 5-Axis machining strategy provides you with sophisticated options for approach/link control, tool axis control and collision avoidance.

- Link and approach moves are fully gouge protected and different strategies may be used depending on the distance of the link move. The feed rate may also be varied on the link moves to allow for asmooth approach to the part.

- SolidCAM also provides you options for controlling lead/lag and side tilt angles giving you complete control over the final tool path.

Sim. 5x Features

Sim 5x Parts for Download

Previous

- SolidCAM's Sim. 5x features specific solutions for SWARF, Multiblade,Port, Contour 5x, Multiaxis drill, Conversion of HSM to Sim 5x,Multiaxis roughing and Rotary machining.

- Flowline cutting gives you a tool path that follows the natural shape of the component - you will find this particularly useful with blade type components.

- Sim. 5x uses multiple advanced Tool Tilting Control to provide you with unlimited control of tool angles.

- Multi-surface finish allows you to select multiple faces/surfaces providing you with full control of your machining for the smoothest surface finish.

- Multi-pass roughing techniques provide multiple cut increments along, and perpendicular to the tool vector, with the option to contain to boundaries and trim to stock.

- Keep your Tool and Holder safe with multiple, automatic Gouge Avoidance strategies that check each part of the tool assembly (shank, arbor, and holder) to the drive and check surfaces.

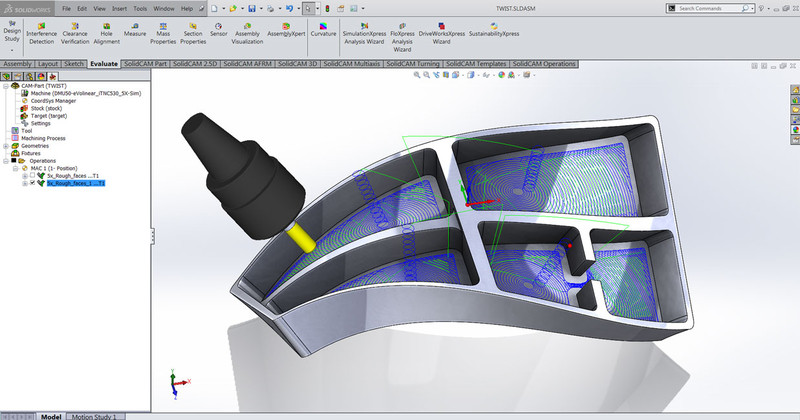

- Get the whole picture with realistic 3D Machine Simulation, complete with comprehensive collision and axis limit checking.

- SolidCAM's 5-Axis machining supports all your rotary kinematics,including Table/Table, Table/Head and Head/Head configurations as well as the latest multi-function Mill-Turn machining centers.

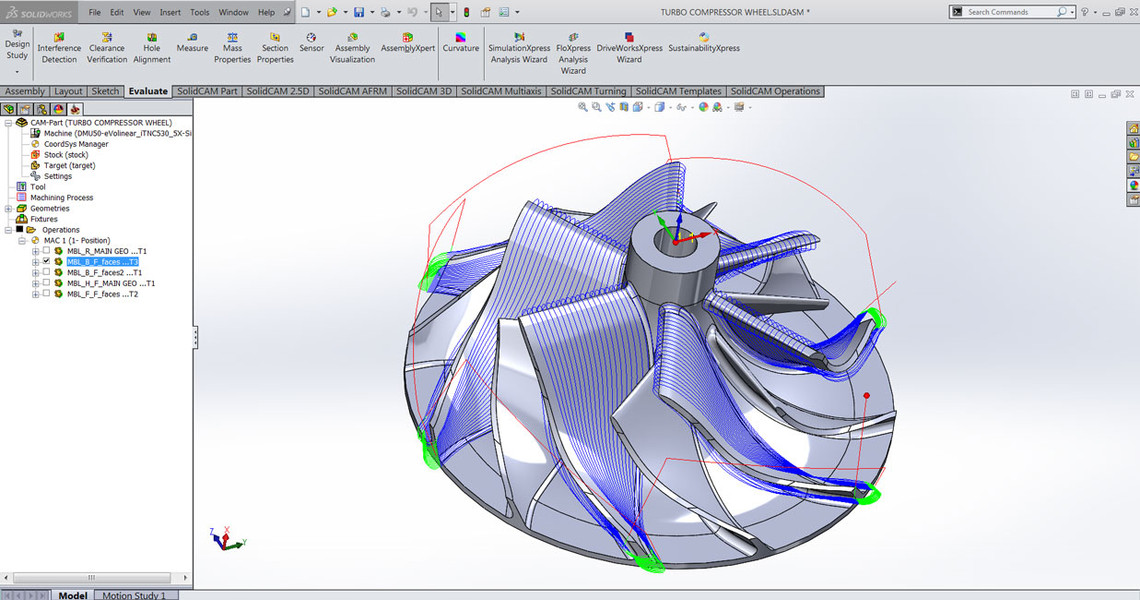

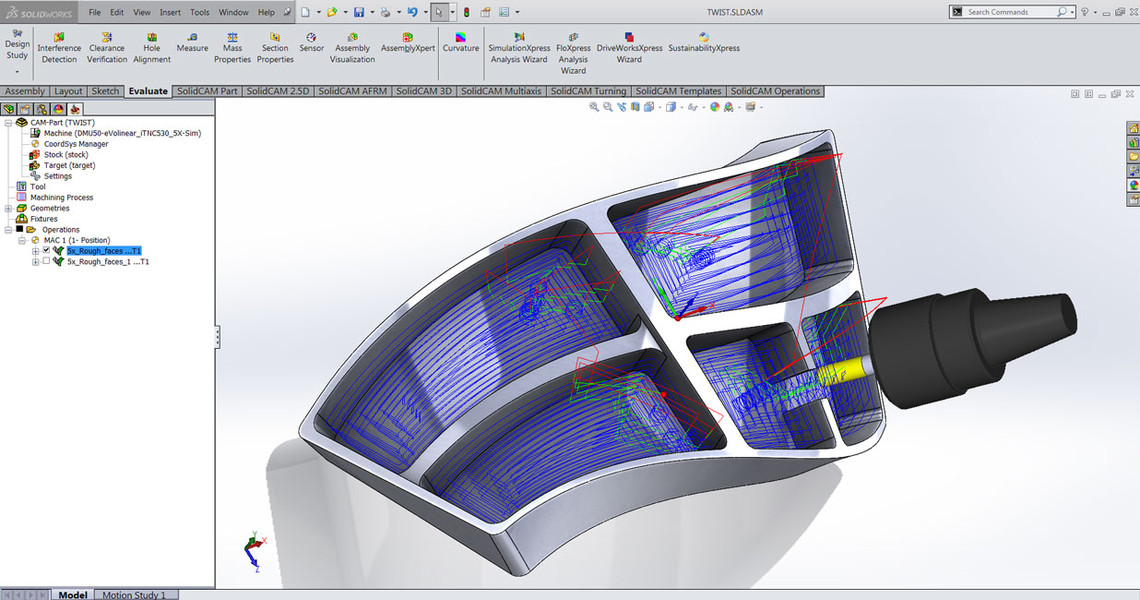

Five New Sim. 5x Operations

The latest version includes major enhancements to the Sim. 5x module. Five new operations have been added to the Sim. 5x module: Multiblade machining, Port machining and Contour 5-axis machining, Multiaxis roughing, and Rotary machining making it the most powerful system in the industry.

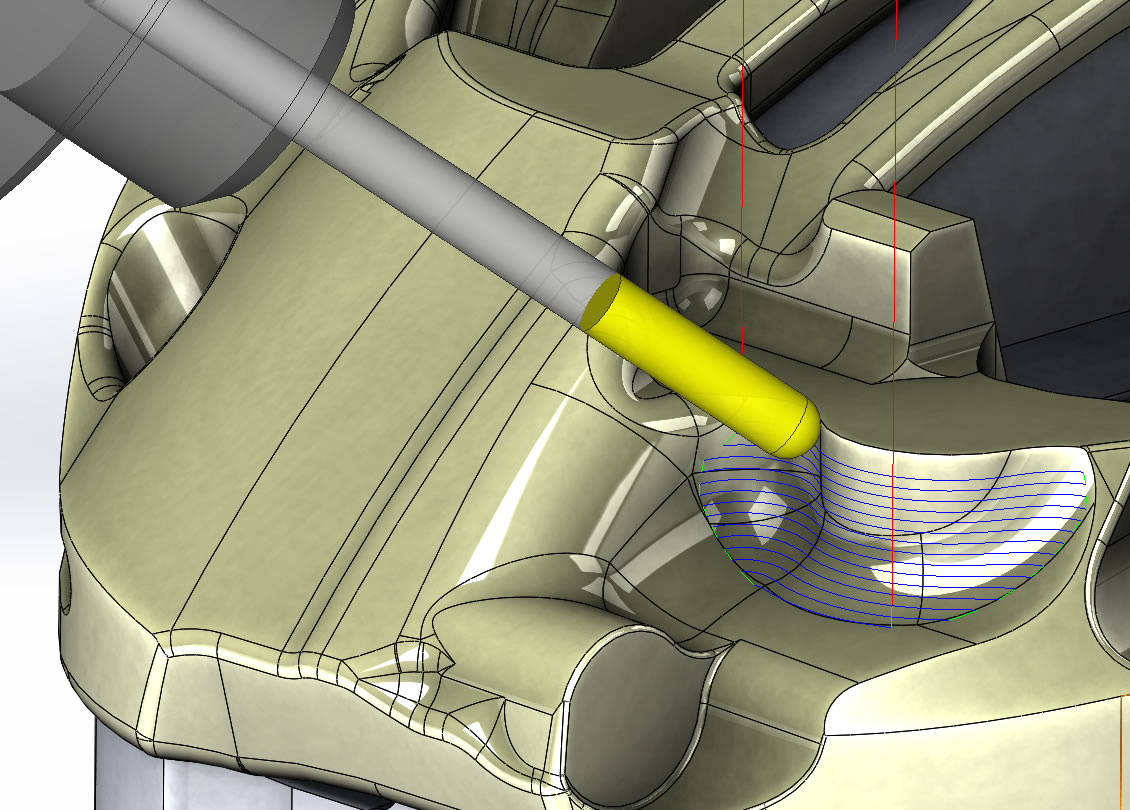

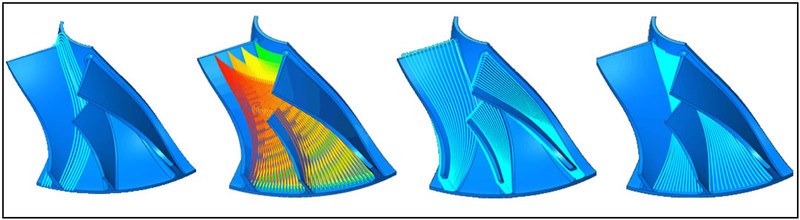

Multiblade Machining

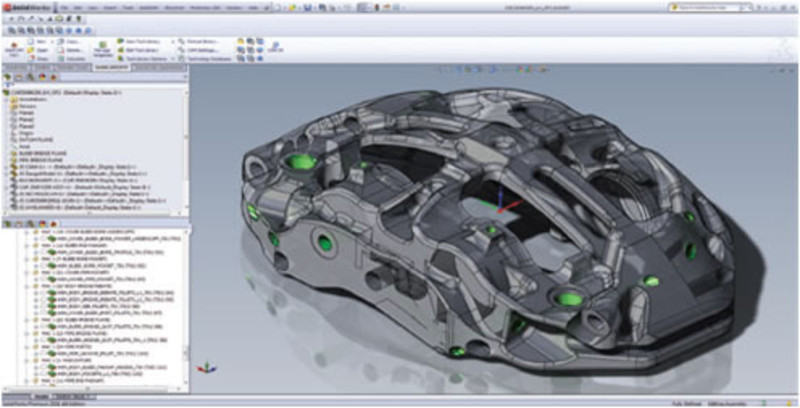

SolidCAM takes the frustration and complexity out of machining multiblade impellers, wheels and disks with the new Multiblade Machining module, which includes operations for roughing and finishing each part of these complex shapes. This new module is specifically designed to easily generate the necessary tool paths for various multiblade configurations - you can even machine all blade surfaces in a single operation.

Multi-Blade Machining

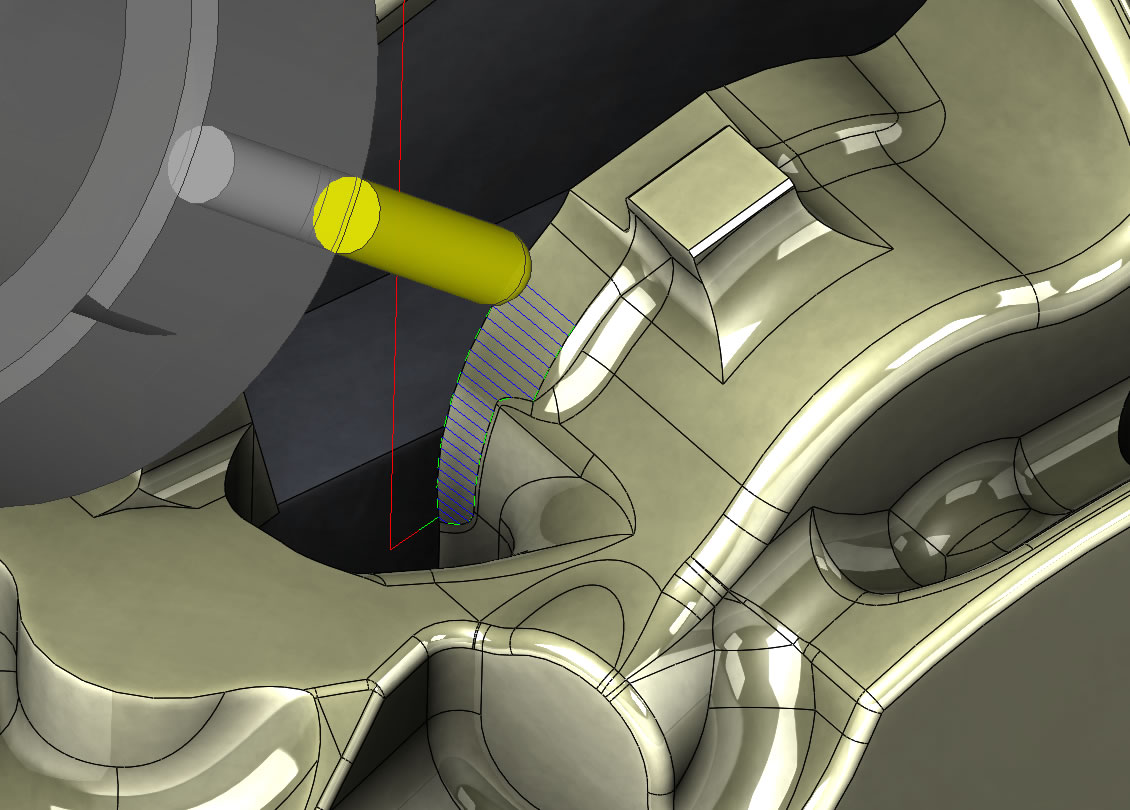

Port Machining

The new Port Machining module enables you to easily machine ports with standard or tapered lollipop tools, and has collision checks for the entire tool assembly (shank, arbor, and holder). You can choose from several strategies including cutting the top only or bottom only. Port Machining uses 3-axis machining as far into the port as possible, and then switches to 5-axis motion. The system automatically overlaps top/bottom strategies to ensure smooth transitions where the tool paths meet. Bothroughing and finishing tool paths are provided and stock can be represented as castings or billet.

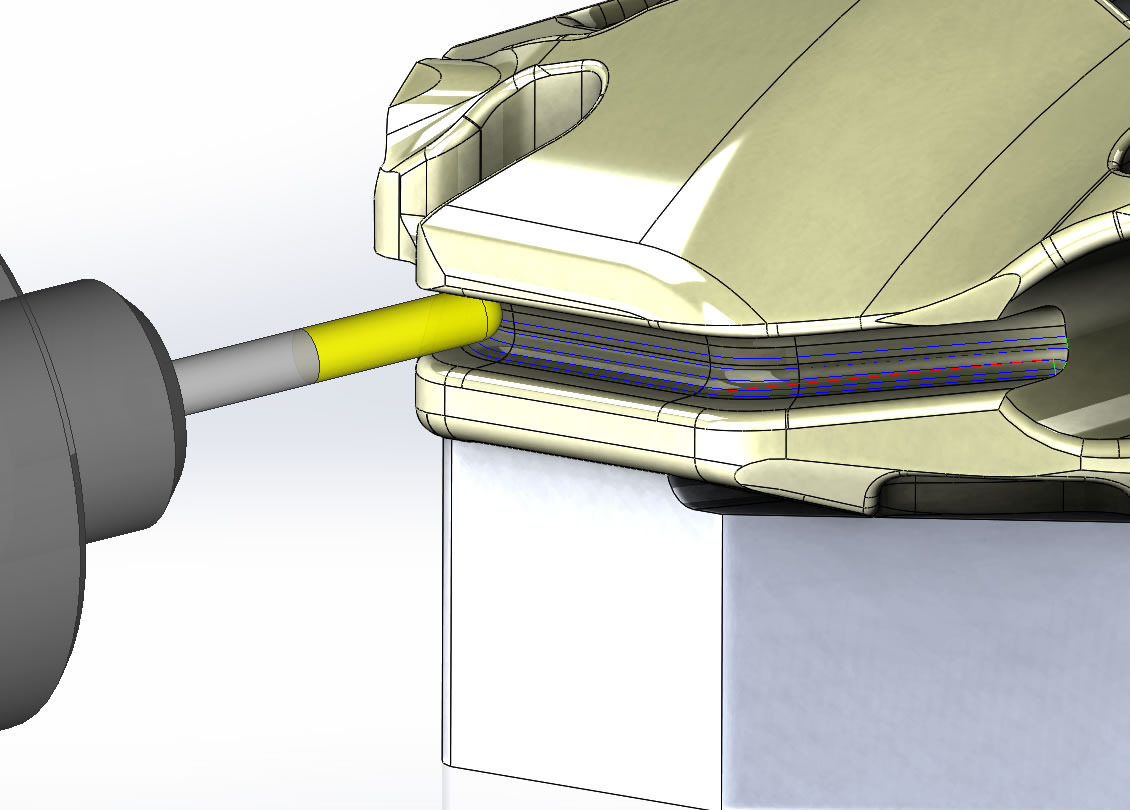

Contour 5-Axis Machining

Contour 5-axis Machining

The new 5-Axis Contour Machining strategy tilts the tool along a 3D chained profile, aligning the tool axis according to user-defined tilt lines, making it ideal for deburring and trimming.

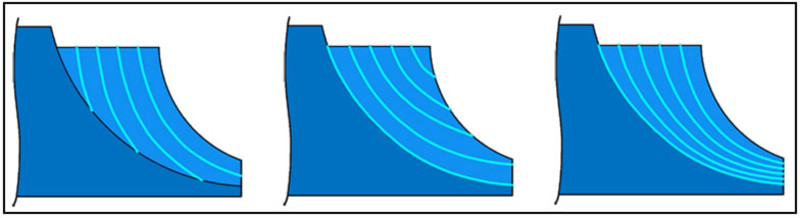

Multiaxis Roughing

The new Multiaxis Roughing operation is used to rough out pocket shaped geometries. You can specify the inputs for floor, wall and ceiling surfaces which SolidCAM uses to identify the constraints of the roughing tool path. Two types of strategies are available: Offset-Based and Adaptive Roughing.

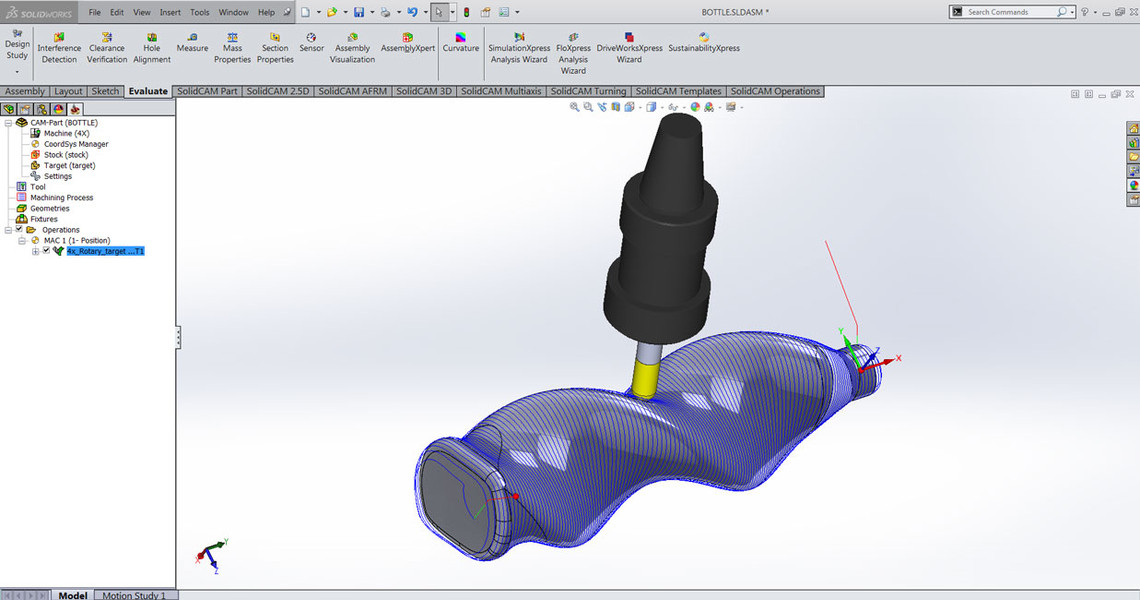

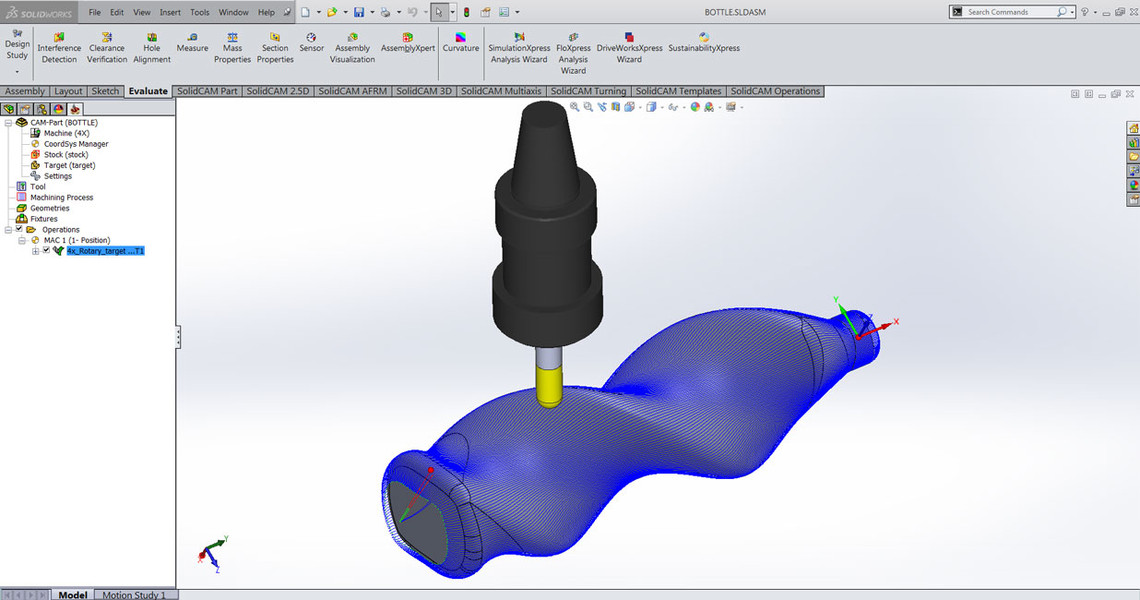

Rotary Machining

The new Rotary Machining operation is designed to mill parts on a 4-axis machine, and can be used to mill cylindrical parts like bottle molds, cores and electrodes. The tool paths are directly calculated on the model instead of being wrapped from 2D geometry.

New Enhancements to Swarf, Multiaxis Drill & the Convert HSM to 5x Operations

Experience New tilting options and enhancements that have been added to the SWARF, Multiaxis Drill and Convert HSM to Simultaneous 5xoperations. These enhancements give you more power in your Sim. 5x operations to reduce programming time, improve product quality and minimize scrap.

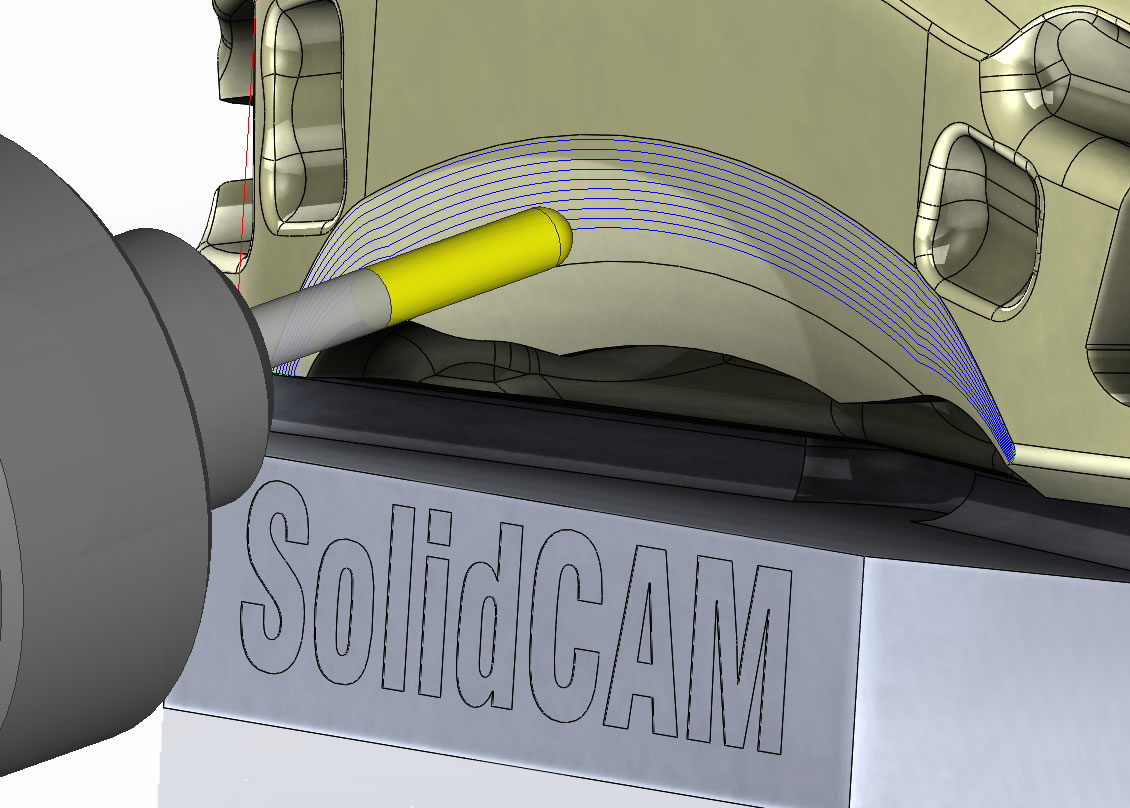

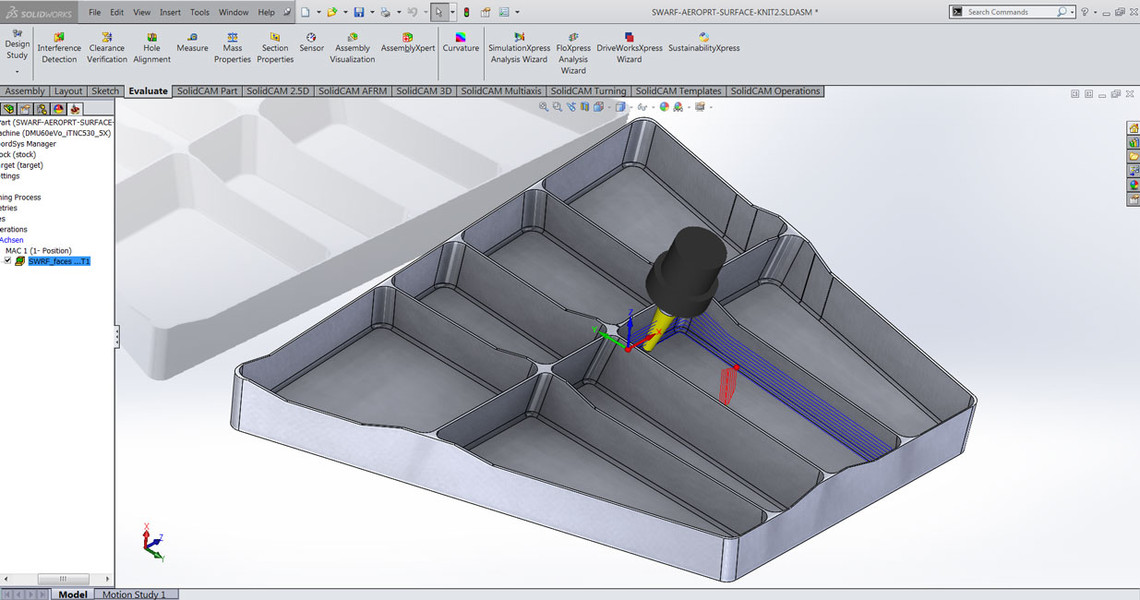

Swarf Machining

Swarf Machining lets you use the side of the tool to machine the wall at the best possible angle. Swarf cutting uses the most effective cutting length of the tool, resulting in better surface quality and shorter machining time.

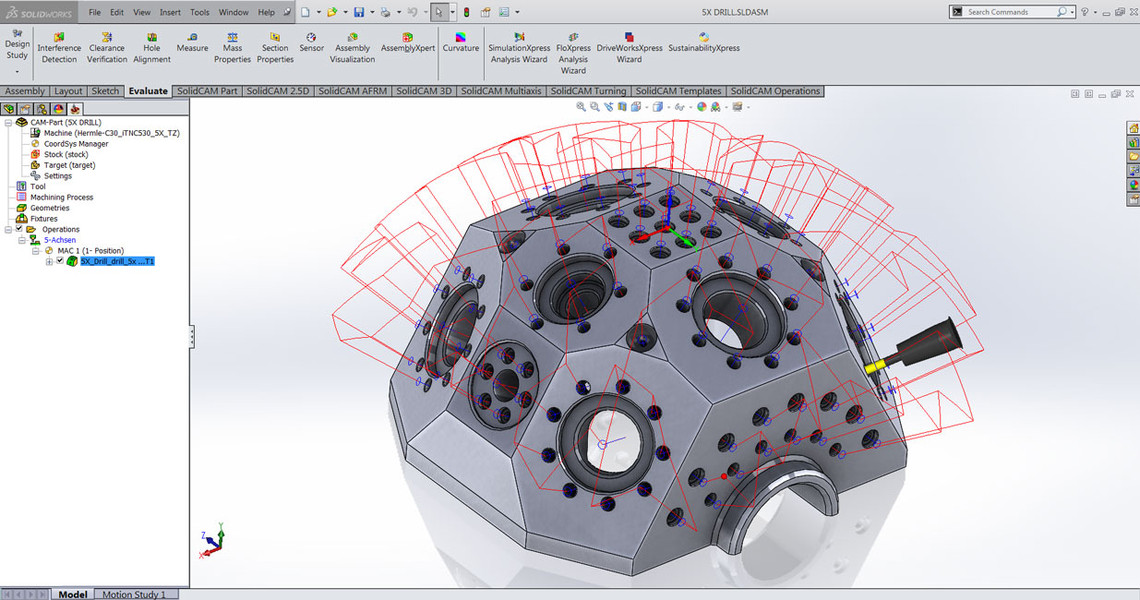

Multiaxis Drilling

The Multiaxis Drilling operation takes advantage of SolidCAM’s automatic hole recognition to allow you to quickly and easily create drilling, tapping and boring cycles along any hole alignment. All the advanced linking, tilting and collision avoidance strategies available in other Sim. 5x operations are also available in this operation, providing full control of the tool path.

Convert HSM to Sim. 5-Axis Milling

Use the Convert HSM to Sim. 5-Axis milling operation to take advantage of the HSM 3D tool paths by applying full 5-Axis tool-tilting, collision-protection and linking strategies, enabling the use of shorter tools for more stability and rigidity.

CAM模組

如何購買

仕堃國際股份有限公司

- SCTW.Co.,Ltd

- Add:台南市安南區工業二路31號 研三館405A

- 709 Room.405A, Research Building 3, No.31 Gongye 2nd Rd., Annan Dist., Tainan City Taiwan

- Tel:06-3841152 |Fax:063841153

- 0800@solidcamtaiwan.com

- www.solidcamtaiwan.com